management | Tagatic

The key in the implementation of 5S is not to avoid errors. On the contrary - implementing new solutions requires openness to their commitment. Mistakes and failures are inscribed in the way of changes.

Savings at the purchase stage can bring losses in long -term use. This also applies to industrial markings. Although they seem cheap, cottage markings are short -lived and generate high exchange costs. By investing in lasting solutions, companies can save tens of thousands of zlotys on specific products. The long -term benefits of visual management should be taken into account when planning the BHP budget and process optimization.

Saving time, minimizing waste, and increasing efficiency – this is the dream of every company in these times of cost-cutting and cost-saving. It turns out that visual management may be the key to achieving these goals. Learn effective and affordable methods that will help your company eliminate waste and achieve a significant return on investment.

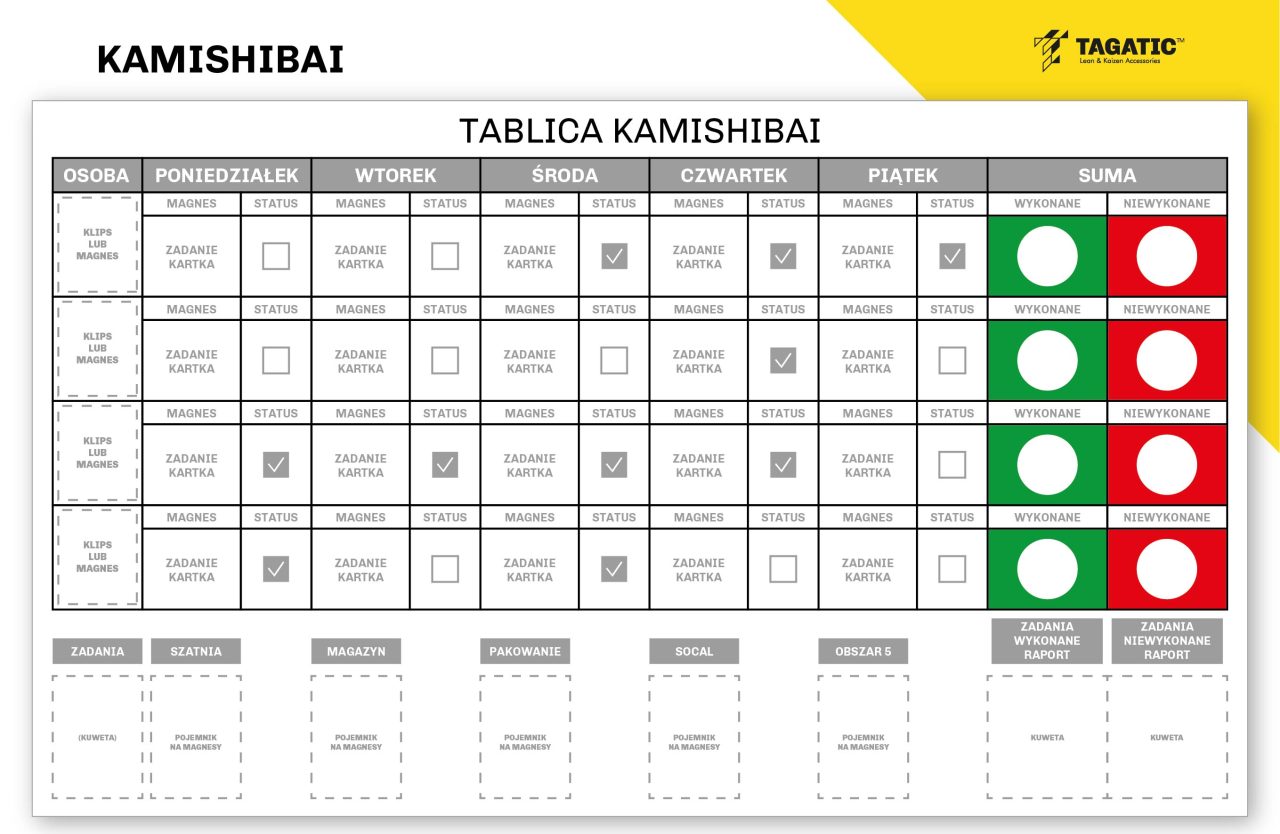

The waste of time in organizations, especially in manufacturing companies, can seriously affect work efficiency. The analysis of research results shows that middle -level employees lose as much as 24% of time on simple activities, such as searching for documentation or transferring a change. How to remedy this problem and increase work efficiency?