Marking as the basis for safety in production spaces

Safety is key in any production environment. Ensuring employee protection, operational efficiency, and minimizing the risk of accidents are the primary responsibilities of plant managers and occupational health and safety experts.

The issue of safety is, of course, complex and multifaceted, but the foundation for creating a safe work environment is the development of procedures that can be effectively implemented within the company. In this regard, visual solutions are invaluable, as they allow for the translation of applicable rules into simple, visible, legible, and understandable messages for employees.

Types of markings

Correct signage helps employees identify hazards and follow appropriate safety procedures. What solutions work best in this regard?

- Informational signage: Placing informational signs in a visible location provides employees with important information regarding safety procedures. Signs can include instructions, warnings, emergency procedures, emergency numbers, and important contacts. It's important that signs are placed in locations where they are easily visible and accessible to all employees.

- Evacuation signage: In the event of an emergency, such as a fire or accident, evacuation signage is crucial for employee safety. Using signs indicating evacuation routes, assembly points, and the location of fire extinguishers helps ensure employees know what to do in an emergency. These signs should be strategically placed and regularly checked to ensure they are visible and legible.

- Hazardous Area Marking: Marking areas with potential hazards is crucial to ensuring employee safety. Examples include marking hazardous machinery, areas with limited visibility, areas with high noise levels, and areas requiring the wearing of special protective equipment. This also applies to paths and equipment routes, such as forklifts. Clear markings inform employees of potential hazards and remind them to exercise caution.

Example solutions

Defining potential threats and developing procedures is only the first step in ensuring security. The most important thing is to ensure that these procedures are understood, effectively implemented, and, therefore, followed. The range of solutions in this area is very broad, encompassing both standard and non-standard tools.

- Labels and stickers: Used on machines, tools, and materials, they allow for quick identification of their purpose, technical condition, and safety requirements. For example, a label advising the user to wear gloves or safety glasses when using a given tool can significantly reduce the risk of injury.

- Mirrors: This simple solution allows employees to verify that they haven't forgotten any of the required attire. A quick glance allows them to assess whether they've followed the required procedures.

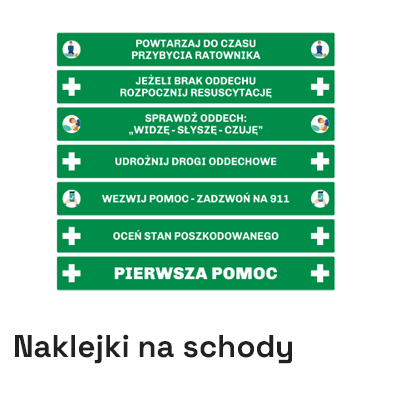

- Stair stickers: a simple yet extremely effective solution for communicating emergency procedures, such as those related to accidents or fires. Listing the procedure in bullet points on each stair allows employees to see the rules and learn… every step of the way

- Visual instructions and procedures: Instead of relying solely on text-based instructions, consider using visuals. Images, diagrams, and charts can help convey information more effectively and minimize the risk of errors. This will make it easier for employees to understand instructions and be more aware of hazards.

- Lines and Markers: Using lines and markers on the floor can help organize space and prevent accidents. Lines can designate safe walking areas, material storage areas, or vehicle paths within a warehouse. Markers can also indicate areas where extra caution is required, such as areas with a high slip hazard or suspended objects.

Tagatic has been supporting its clients in improving workplace safety for years. We offer boards, tapes, stickers, markers, mirrors, stair decals, and many other accessories tailored to safety requirements. We also provide support with audits, identifying needs, and signage design. If you're looking for a way to improve safety in your factory, you've come to the right place.