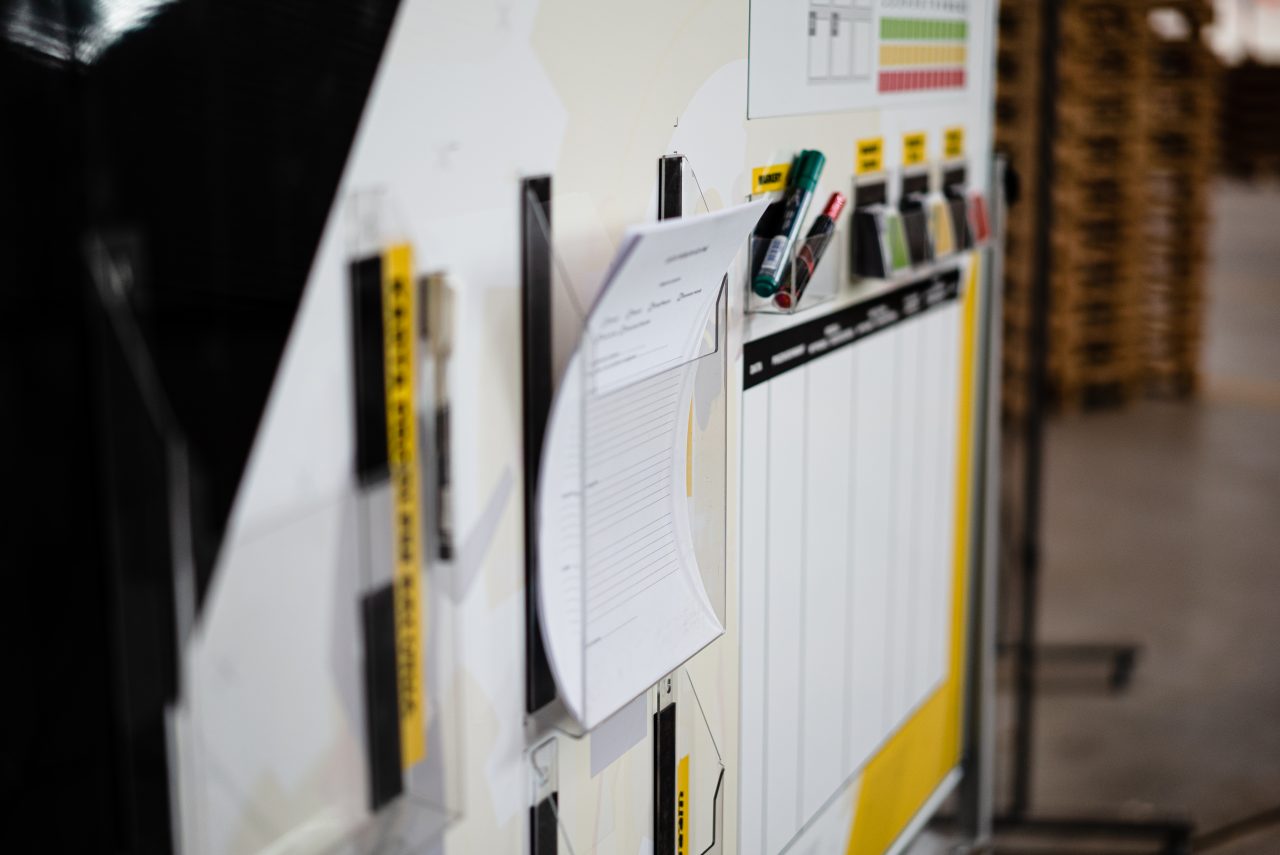

Effective management of documentation in the workplace is the key to increasing performance, elimination of waste of time and ensuring clear work standards. This issue applies to both industrial spaces, such as factories, warehouses and logistics centers, as well as office spaces. What tools allow you to effectively manage the circulation of documents?

Tagatic Blog - Experts in Visual Signage Production

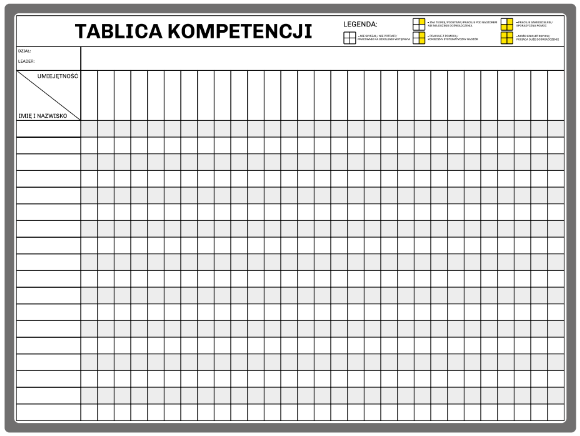

Competency boards, also known as competency matrices, are an invaluable workforce management tool. They help organizations understand their employees' skills, identify competency gaps, and plan team development. However, for such a board to be truly useful, it must be properly designed and visualized.

The key in the implementation of 5S is not to avoid errors. On the contrary - implementing new solutions requires openness to their commitment. Mistakes and failures are inscribed in the way of changes.

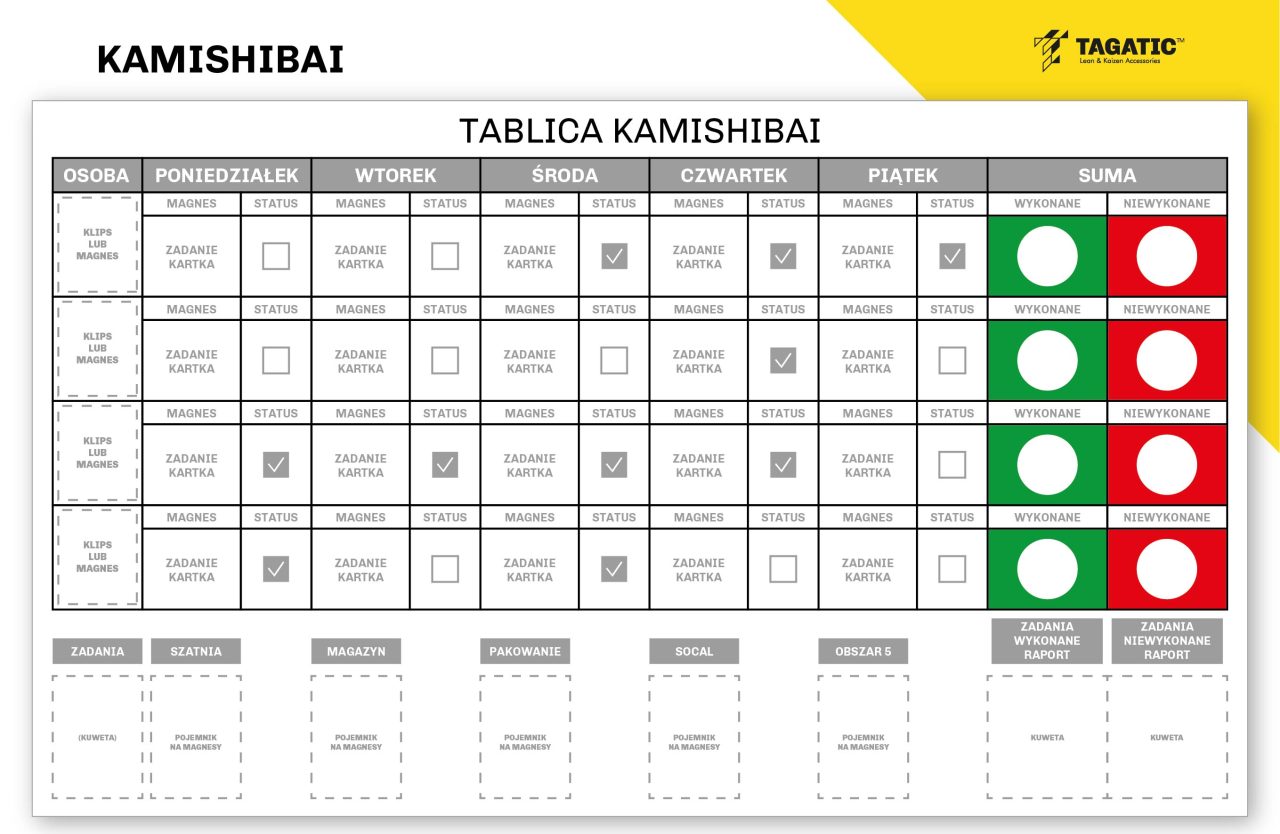

How to use boards for managing people and processes in the production environment? How to create a board design that meets your needs? How to check its usability? Damian Małolepszy in our latest video answers these questions.

Savings at the purchase stage can bring losses in long -term use. This also applies to industrial markings. Although they seem cheap, cottage markings are short -lived and generate high exchange costs. By investing in lasting solutions, companies can save tens of thousands of zlotys on specific products. The long -term benefits of visual management should be taken into account when planning the BHP budget and process optimization.

Saving time, minimizing waste, and increasing efficiency – this is the dream of every company in these times of cost-cutting and cost-saving. It turns out that visual management may be the key to achieving these goals. Learn effective and affordable methods that will help your company eliminate waste and achieve a significant return on investment.

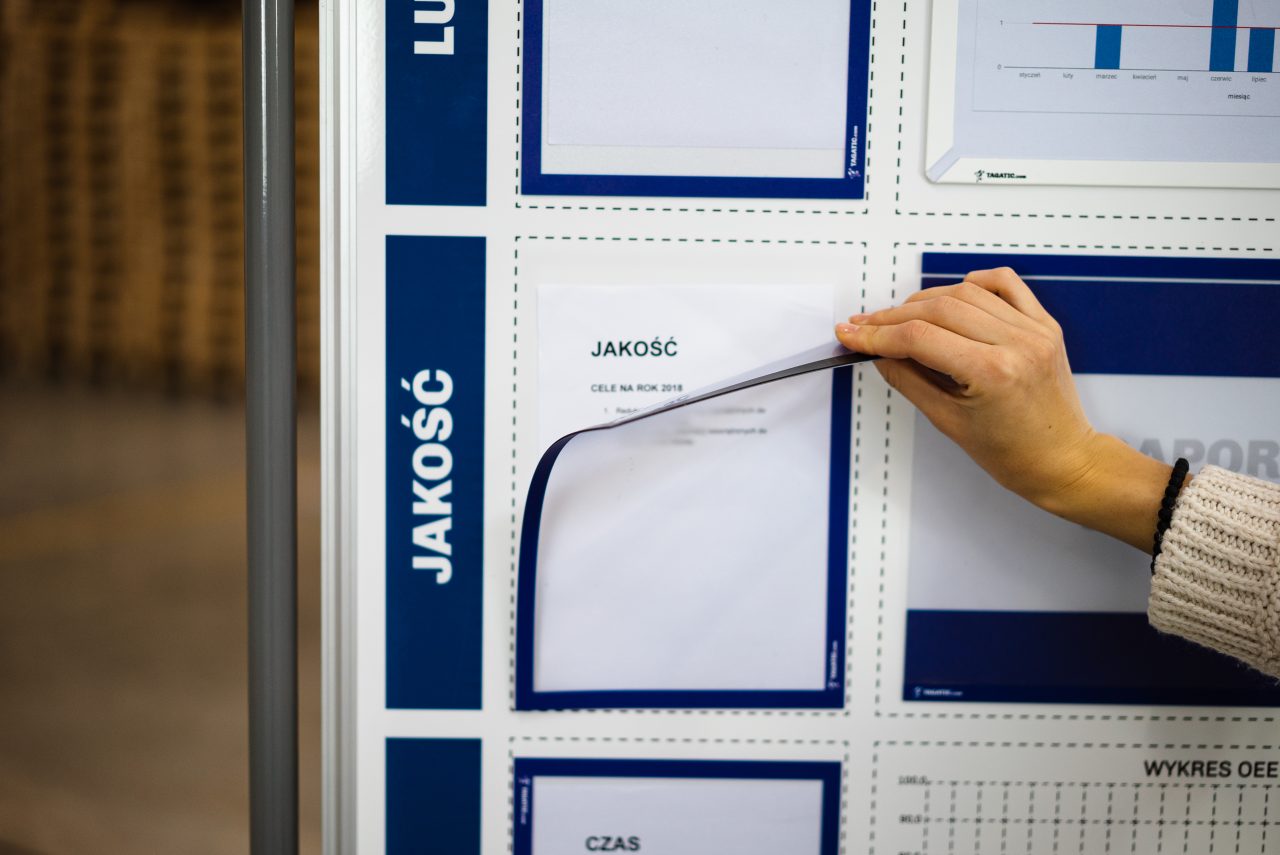

The waste of time in organizations, especially in manufacturing companies, can seriously affect work efficiency. The analysis of research results shows that middle -level employees lose as much as 24% of time on simple activities, such as searching for documentation or transferring a change. How to remedy this problem and increase work efficiency?

Effective and thoughtful design of marking, transport and logistics is the key to creating a safe, effective and profitable work space. By improving the organization of processes and ensuring adequate marking, the company can achieve greater performance, reduce costs and increase the margin.

Discover three innovative Tagatic visual management solutions that not only minimize the risk of accidents, but also reinforce good habits, reduce absenteeism, and solve specific problems in warehouses and industrial plants.

Attract the best employees with interior design and appropriate space signage! Safety, aesthetics, and creativity are the foundations of successful employer branding!