What really is 5S?

Reading books related to the 5s methodology or browsing articles available on the Internet, we can meet with various development of subsequent "S". We can also come across many academic discussions on how to correctly explain subsequent stages into Polish.

So let's see what it looks like at the source, i.e. in the land of the rising sun.

- Seiri

- Seiton

- Seiso

- Seiketsu

- Shitsuke

The concepts themselves won't tell us much unless we know Japanese. Perhaps the English version will tell us a little more:

- Sort

- Set in order

- Shine

- Standardize

- Sustain

Okay, but what do these terms really mean?

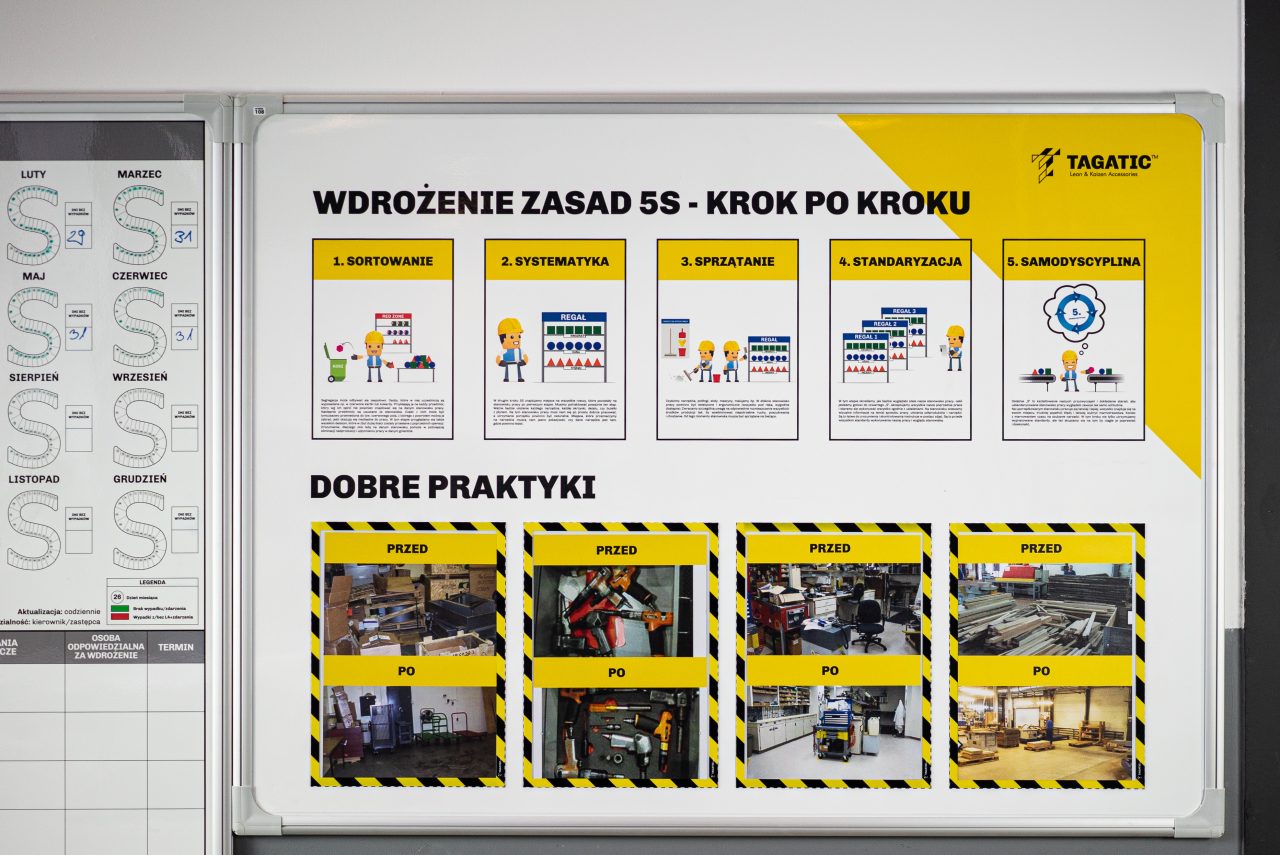

SORT

The first step is most often translated as "selection," and it quite accurately captures the activities that must be performed at this stage. It can also be translated as "sorting." The first and most important task, without which the subsequent stages cannot be proceeded, is to divide everything in the workstation and its surroundings into necessary and unnecessary items. It's worth using the "red tag" method here. Its purpose is to label everything in production and offices that is not required for work.

SET IN ORDER

The second pillar is explained as systematics or systematization. Simply put, it involves finding a place for everything essential in the workplace. Knowing how often individual items are used and where exactly they are located will be crucial here, as this will determine the equipment's location. It's obvious that it's impossible to place everything "at hand," as this would create the very mess we want to eliminate. At this stage, we should determine what, how much, and where it will be located.

SHINE

It's simply cleaning. When conducting 5S workshops in the workplace, it's important to thoroughly clean the workstation and its surroundings at this stage. However, this isn't a one-time activity. Once the entire facility has been restored to its baseline condition, it's important to consider what tasks should be performed regularly to maintain this condition. The planned cleaning schedule should also include inspections and checks, which will allow us to assess whether the equipment at our workstation is fully functional and ready for use.

STANDARDIZE

Standardization, the fourth pillar of the 5S concept, involves standardizing what was established in the previous three steps. Masaaki Imai understands standardization not only as adhering to established rules but also as "continuous, daily work on seiri, seiton, and seiso." In practice, this means regularly revisiting selection, systematization, and cleaning, as well as improving established standards. It's important to establish who will be responsible for initiating these activities and how often.

SUSTAIN

Literally translated, this means "maintenance," but the final pillar is most often called self-discipline or self-improvement. This emphasizes the importance of maintaining new habits and striving for excellence. It's crucial to engage the entire team and support each other. Audits are used to assess the level of implementation of individual 5S steps, allowing us to identify further areas for improvement.

Ultimately, how we translate individual steps isn't the most important thing. What's far more important is understanding the concept and consistently taking steps to improve our jobs.