Time waste in the organization - analysis of research results

24% – this is the average amount of time mid-level employees in manufacturing companies waste on simple tasks like reporting, searching for documentation, or handing over shifts. This is the result of a report published by KanriSoft. The results for production workers are similar. Is time-wasting inherent in the nature of business operations? Or can it be prevented?

Wanted – wanted

What do middle managers waste their time on? Searching for:

- Searching for job documentation takes an average of 11 minutes during an eight-hour shift

- Searching for historical data: another 18 minutes on average.

In total, that's nearly half an hour of searching. The problem isn't limited to managers, though – the average production worker spends 16 minutes a day… searching for their manager!

The picture seems paradoxical – the supervisor is looking for documentation, the employee is at the same time looking for the supervisor… and this is only the tip of the iceberg.

Transmitting and waiting

Managers waste the most time handing off shifts, while production workers waste the most time waiting for components. Both processes take an average of 38 minutes per shift.

This means that a production worker wastes an average of 54 minutes per day waiting for components and searching for a supervisor. That's over 11% of their shift!

A manager spends as much as 14% of their time searching for documentation, historical data, and transferring change. But… that's still not all.

Count

Another activity that takes up a manager's time is counting:

- OEE calculation: 33 minutes on average

- counting produced pieces: 10 minutes on average

Total: 43 minutes, or another 9% change.

Production workers don't waste time on counting – instead, they waste it on malfunctioning events:

- reporting a failure: 8 minutes on average

- reporting downtime reasons: 9 minutes on average

- Safety reporting: 6 minutes on average

- bug reporting and categorization: 12 minutes on average

Total: Another 35 minutes. Another 7% change.

Causes

In total, mid-level employees spend an average of 117 minutes on these activities (and others like them), while production workers spend 101 minutes. This equates to 24% and 21% of their time, respectively. This means that between one-third and one-quarter of their time is spent reporting, searching, filing, and forwarding.

This is most often due to errors not only in the arrangement of the processes themselves, but also – and perhaps above all – in their readability and practical functioning.

Employees waste time searching for tools because there are no standards for their storage and placement. They wait for components because there is no adequate system for labeling and reporting current material levels.

The supervisor takes 38 minutes to hand over the shift because there's no clear reporting system, data visualization, or current status. He's searching for documentation because there's no proper document storage and circulation system.

Can this be remedied? Of course it can!

Prescription

Beyond setting up processes, proper communication and visualization are crucial. Well-chosen, well-thought-out signage tailored to the company's needs can help.

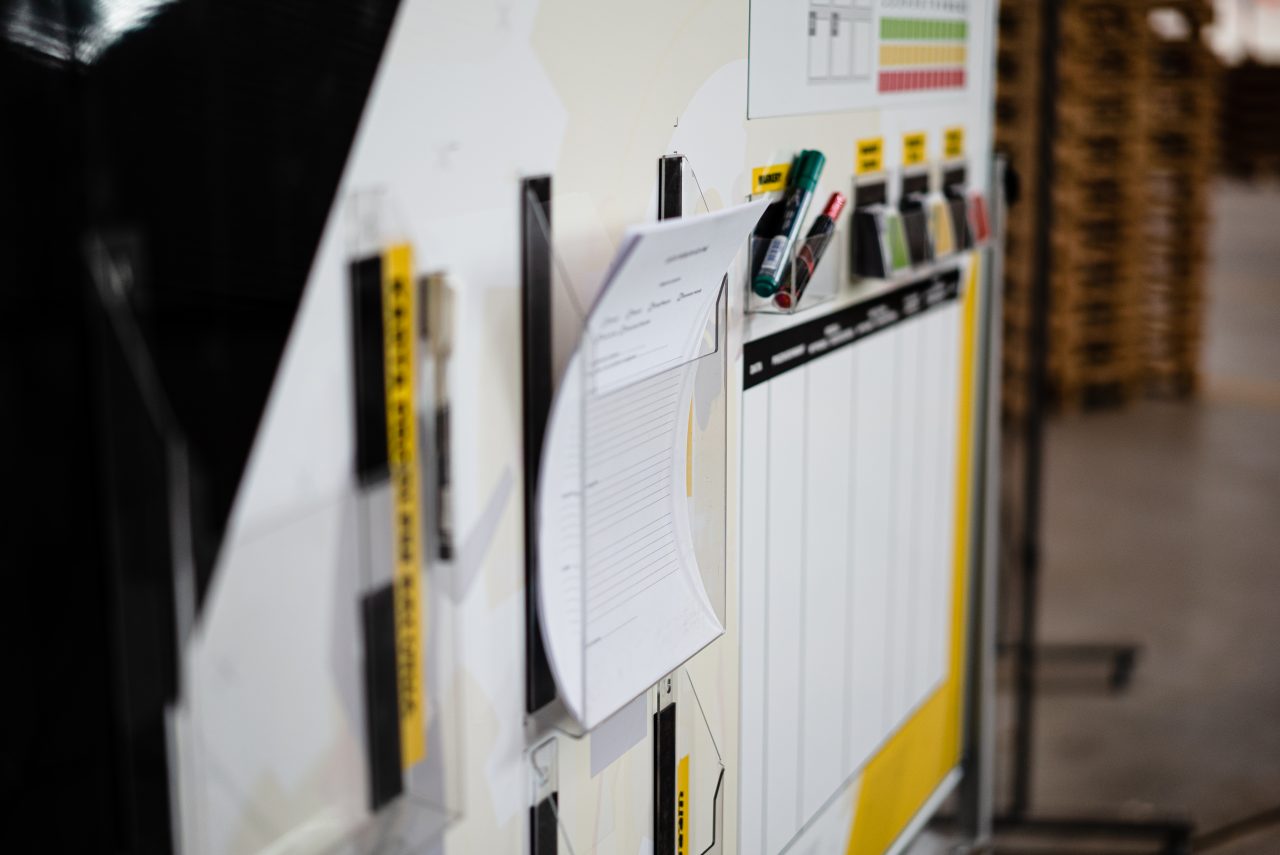

- Dry-erase boards (used, for example, as KanBan or FIFO boards) allow for clear and transparent management of people and processes for all employees. Placed in a highly visible location, they become a focal point for production management. Information is clear, concise, legible, and communicated quickly and in a way that everyone can understand. This saves time for both employees and managers.

- Appropriate marking of minimum stock levels allows for on-time delivery of components. Shadow boards ensure that employees always have all the necessary tools at hand. This means they stay at their workstation longer and avoid wasting time.

- Tapes, stickers, horizontal, vertical and hanging markings – all these elements allow for better orientation in space, and appropriate marking of roads and potential dangers not only improves logistics but also reduces the risk of accidents.

First step

There are a wide range of visual solutions that support management by reducing time waste, increasing efficiency, and enhancing safety. The key is to properly design the entire signage system and implement solutions that are visible, intuitive, and effective in the given environment. Therefore, it's worth starting with an audit of current processes and signage, and then embarking on a process of change that—carefully planned and considered—will positively impact the efficiency of the entire enterprise.

At Tagatic, we've been supporting manufacturing companies in creating safe and effective work environments for years. Schedule a free audit and learn how we can help your company.