Dry -erase boards - the heart (and brain) of the production space

A key aspect in any production environment, where organization and efficiency must be at the highest level, are the appropriate tools to maintain operational fluidity.

One of the inconspicuous, yet very popular tools used in industry are dry-erase boards.

Management, security and information

While dry-erase boards may seem useful only for taking notes or jotting down conclusions during meetings, their functions can be quite diverse, and their usefulness is invaluable. The three most important areas of dry-erase board use are:

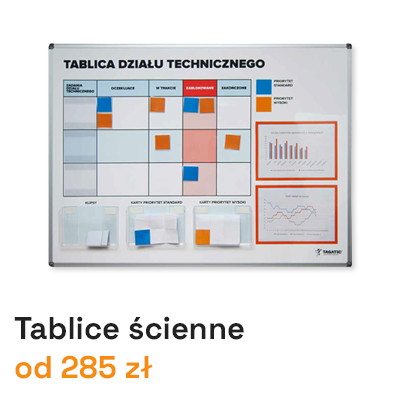

- Management. Dry-erase boards, used as Kanban boards, people management boards, process management boards, or department management boards, enable the collection of all production-related information in one place. They allow for a clear and accessible visualization of the production plan and tasks to be completed.

- Safety. Properly used, dry-erase boards can be used to present key procedures, establish traffic rules, and provide information on where to find appropriate personnel.

- Information boards. Their use eliminates the need for searching. Properly labeled warehouses, tools, raw materials, and semi-finished products shorten the work process and make the company more efficient.

Efficiency and communication

In production halls, warehouses, and logistics centers, there are often numerous tasks to complete, production schedules, material lists, and other important information. Dry-erase boards can serve as a central communication point, displaying information in a clear and easily accessible manner. This allows the entire team to stay well-informed about current priorities, schedules, and procedures, resulting in increased efficiency and fewer errors.

These boards save managers time by having all information clearly stored in one place. Using the board, managers can assign all tasks, which become immediately visible to employees. Boards can also be useful for outsiders trying to navigate the space and find the right person. This facilitates communication, improves movement within the facility, and thus improves safety.

Motivation and appreciation

Another use for whiteboards is tracking progress and setting goals. Whiteboards can be used to track production performance, monitor key metrics, and record goals and achievements. Employees can write on the whiteboards information about the number of units produced, process times, and any other progress metrics. This, in turn, allows for both motivating employees to achieve better results and identifying areas for improvement.

An example of such an application is 5S boards. Within this methodology, dry-erase boards are used at each of the five stages: sorting, setting in order, cleaning, standardizing, and sustaining, serving to visualize, identify, and organize the production space. Importantly, the boards not only remind employees of 5S principles but also demonstrate progress by posting before-and-after photos. This simple technique can achieve a motivational effect – highlighting implemented changes, emphasizing satisfaction with their implementation, and appreciating the employees responsible for them.

KanBan boards

Kanban, which means "visibility board" in Japanese, is a tool that is part of the production system introduced by Toyota and is designed to ensure the right amount of materials, parts, or tasks are in the right place at the right time.

Kanban boards are commonly used to monitor and manage elements of the production process. For example, a Kanban board can be used to track the availability of raw materials and supplies in a warehouse, control inventory levels, or plan production. Kanban cards are moved around on the board as the process progresses, informing employees of current status and needs. Instead of cards, we can also use magnets, which are durable and equally practical. This solution is often chosen by our clients.

Many companies today use digital whiteboards, but physical dry-erase boards are still essential in production spaces. By placing a whiteboard in a visible location for all employees, information regarding tasks, deadlines, and work progress becomes easily accessible and legible. Such a whiteboard becomes a true "visibility board," fostering better planning, coordination, and collaboration between teams, leading to improved production efficiency and effectiveness.

Additionally, using dry-erase boards allows for the easy creation and updating of task lists, production schedules, reminders, and other important information. This flexibility allows the KanBan board to quickly adapt to changing needs and priorities in the production process. When used in this manner, problems such as material shortages, delays, or downtime can be quickly identified, allowing for immediate corrective action.

Versatile and adaptable

The fundamental question you should ask yourself before ordering a dry-erase board is its intended use. Implementing boards without prior thought and adaptation to the needs of the company usually means they will quickly fall out of use.

The board's format—resembling Excel, tables, or posters—is secondary to the needs. The key is to properly consider the board and test it in real-world conditions.

It's also important to remember that simply putting up a board isn't the end of the process. Feedback and improving it to ensure it actually serves employees are crucial. Ultimately, it's them the board is meant to serve – so it must be functional, aesthetically pleasing, and inviting.

Our offer includes both standard boards and those created according to the individual needs of our clients. If you are looking for professional advice on visualizing and streamlining processes in your company, contact us. We are sure to find a solution that meets your needs.