5S - how (not) to avoid mistakes?

The key to implementing 5S isn't avoiding mistakes. Quite the opposite – implementing new solutions requires an openness to making them. Mistakes and failures are inherent in the path of change.

What characterizes the most effective organizations is their response to failures—based not on finding someone to blame, but on a thorough analysis of the entire process, identifying elements that failed and correcting them to avoid repeating the same mistakes in the future. In Japanese, this is called Hansei.

At Toyota, even after a project has been successfully completed, a hansei-kai is held – a meeting to analyze the points that did not go according to plan.

As you can see, learning from your mistakes is essential, but it's definitely better to learn from the mistakes of others. Below, we describe a few mistakes we've seen ourselves. Some we've even made ourselves. We're sharing them to prevent you from rediscovering them.

Treating 5S as a project

In many organizations, at the beginning of 5S implementation, ambitious plans, curiosity, and a desire for change are evident across various positions. Initial changes are visible, and people are engaged, but after a while, the results everyone was so proud of disappear.

When asked what went wrong, the most common answer is a misunderstanding of the fifth S—self-discipline—and treating 5S as a task to be performed, not as a way to change mindsets. 5S isn't something you can "do," just as changing organizational culture isn't something you accomplish in a month. 5S isn't a project with a beginning and an end.

It takes months, sometimes even years, of hard work to achieve a change in employee attitudes. When 5S "dies," it's most often due to a lack of self-discipline.

Audit = self-discipline

But how can this be a lack of self-discipline? We have an audit system in place!

We should ask ourselves whether periodic audits are the best solution. Since we're talking about a continuous change process, can it be achieved if we monitor it weekly or monthly?

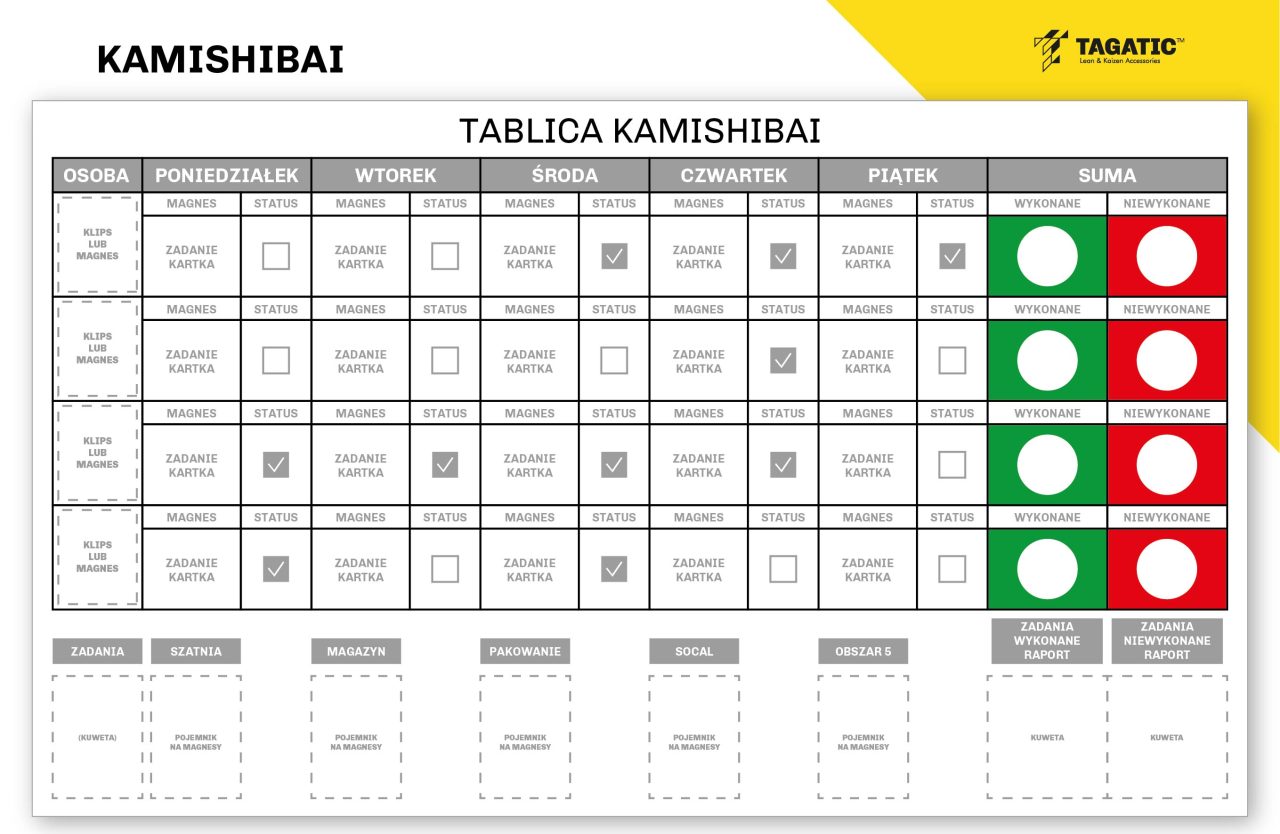

Self-discipline cannot be based solely on a system of audits – it requires continuous work by the entire team. It instills in employees the need to immediately respond to observed non-compliances. Instead of a cyclical auditing system, which, as experience has shown, leads to distortions and, in the long run, unnecessary costs and poor results, a better tool is the kamishibai board.

Let's look at managers and their influence on changing culture in the spirit of 5S, in line with the popular saying "a fish rots from the head down.".

Turning a blind eye to minor deviations from the norm.

How often do we react to deviations from accepted standards when walking through a production hall or office? Unfortunately, very often, in the rush of current tasks and rushing from one meeting to the next, we lose sight of our surroundings. However, this lack of reaction can be perceived as tacit consent to non-compliance with accepted rules and standards.

In this case, we can observe the same mechanisms analyzed in an experiment by Stanford University professor Philip Zimbardo. The experiment involved observing the impact of a response, or lack thereof, to minor damage on the level of vandalism. The conclusions from this experiment show that a failure to respond to minor damage demonstrates a lack of care and adherence to rules, which in turn leads to greater damage and escalation of problems.

If we don't address non-compliance with standards, even in trivial matters, it will be evidence that we condone their violation. This results in diminishing respect for the principles and standards, which is crucial to the 5S method. Importantly, this applies not only to 5S itself. The same applies to all other principles you, as an organization, want to uphold: from occupational health and safety, through work standardization, to implementing the company's vision and mission.

No example coming from above.

Albert Einstein said, "If a cluttered desk is a sign of a cluttered mind, then of what is an empty desk a sign?" This is a common argument raised by management when this issue is brought to their attention. However, from the perspective of the employee, who is required to change their habits, who is required to maintain rigorous tidiness, the situation is quite different.

On the one hand, management conveys the importance of order, but demonstrates something entirely different. This disconnect between what we say and how we behave results in a lack of trust and confidence in the sincerity of our words. It's impossible to change an organization's culture if we don't have the trust of our team.

And what about the situation with inappropriate/insufficient employee involvement in changing the organization's operations from a 5S perspective?

Lack of employee engagement

When we decide to implement changes within 5S, we engage a large team. Not only the people who work in a given position daily, but also their supervisors and supporting departments, led by someone familiar with the 5S method.

With such a large team, unfortunately, the voice of the person in a given position is often overlooked or fails to get through to their superiors. However, this employee will spend most of their working day in this position. They will be evaluating the changes being implemented for most of their time at the company.

Therefore, it's important to listen carefully to his comments and criticism of the proposed solutions. Remember that 5S isn't a one-time effort to create a perfect workplace, but a path to continuous improvement. It's more important to convince employees to use the method than to implement as many changes as possible.

Failure to transfer responsibility

A common mistake made during initial 5S implementations is to delegate responsibility for changes to individuals who are 5S specialists but do not own the area. They are expected to deliver results – a change in work culture. Unless these individuals directly manage the area and its employees, they have no say in determining the priority of activities. They are often assigned to situations where 5S is sidelined – "due to an urgent shipment," "due to a lack of staff," etc.

To achieve success, the owner of a given area should be responsible for the change, and the 5S specialist should provide support. Only when the owner believes in the change and is committed to it is there a chance of success.