Volvo Adaptation of the mounting space

Cooperation

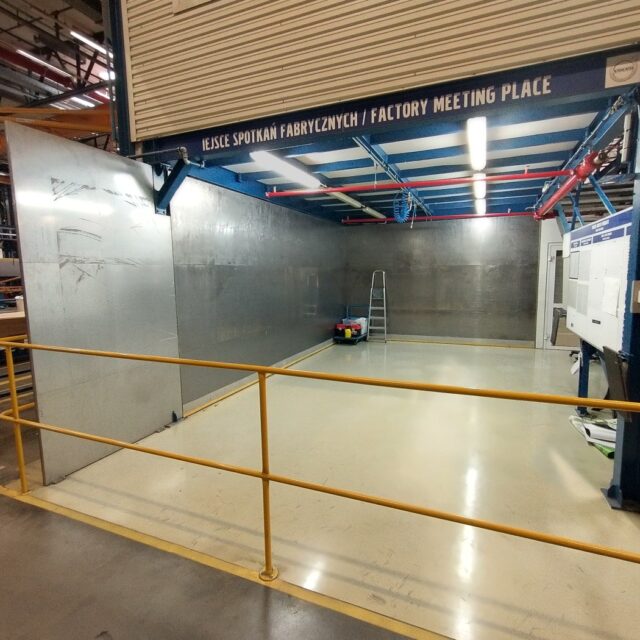

Our main partner on the Volvo side is the Lean Technologies department, but the described implementation was carried out on behalf of Health & Safety Department. The goal was to adapt the mounting hall space in a way that would meet the horns requirements of the Volvo Security Academy.

The client has set a task for us to arrange a surface that will allow all employees to familiarize themselves with applicable safety rules in a comprehensive, and at the same time easy and friendly.

Our activities included the preparation of space within the plant, creating graphic projects, content and assembly of all elements of the Security Academy. We also created a dedicated Brand Hero - the figure of Żak, supporting employees in the science process.

We also took care of the tale of the project, allowing employees to get to know the firefighters and personal protection actually.

Adapting the project to the client's needs

Each element coming out of the Tagatic plant meets strict standards in the field of durability, is characterized by the highest quality, visibility and transparency. Our products operate in industrial conditions, hence their resistance is crucial, but also intuitiveness and intelligibility for employees of the production zone.

The specificity of the Volvo project, however, required adaptation to the client's expectations, the possibilities of production space and cohesion with the other materials of the company.

As part of the order, we used tagatic products such as floor stickers, floor magnets and monomeric foil.

Consultation and advice

The entire implementation was the result of a series of meetings and a multi -week preparation process. It required the creation of dedicated graphic projects (including Brand Hero) and strict adaptation of solutions to the methodology adopted in the company and available space.

The whole process was based on Tagatic knowledge and experience in the field of safety and health and safety rules, as well as on the original concept of the client and his expectations.

Porementation support

We remain in constant contact with our clients, assessing the effectiveness of implemented activities, optimization options and additional needs.

Our approach is based, on the one hand, on standardization (in the field of production and the solutions offered), and on the other - on flexibility, both in cooperation planning and in post -realization activities.