Sewing Department Process Optimization

Introduction

We had the pleasure of working with a client in the manufacturing industry who challenged us to optimize a small process that had a significant impact on production efficiency. The goal was to streamline the card signing process at the sewing stations after the production cycle. The improvement we implemented allowed for an increase in production by 36 products in a single day. How was this possible?

Challenge

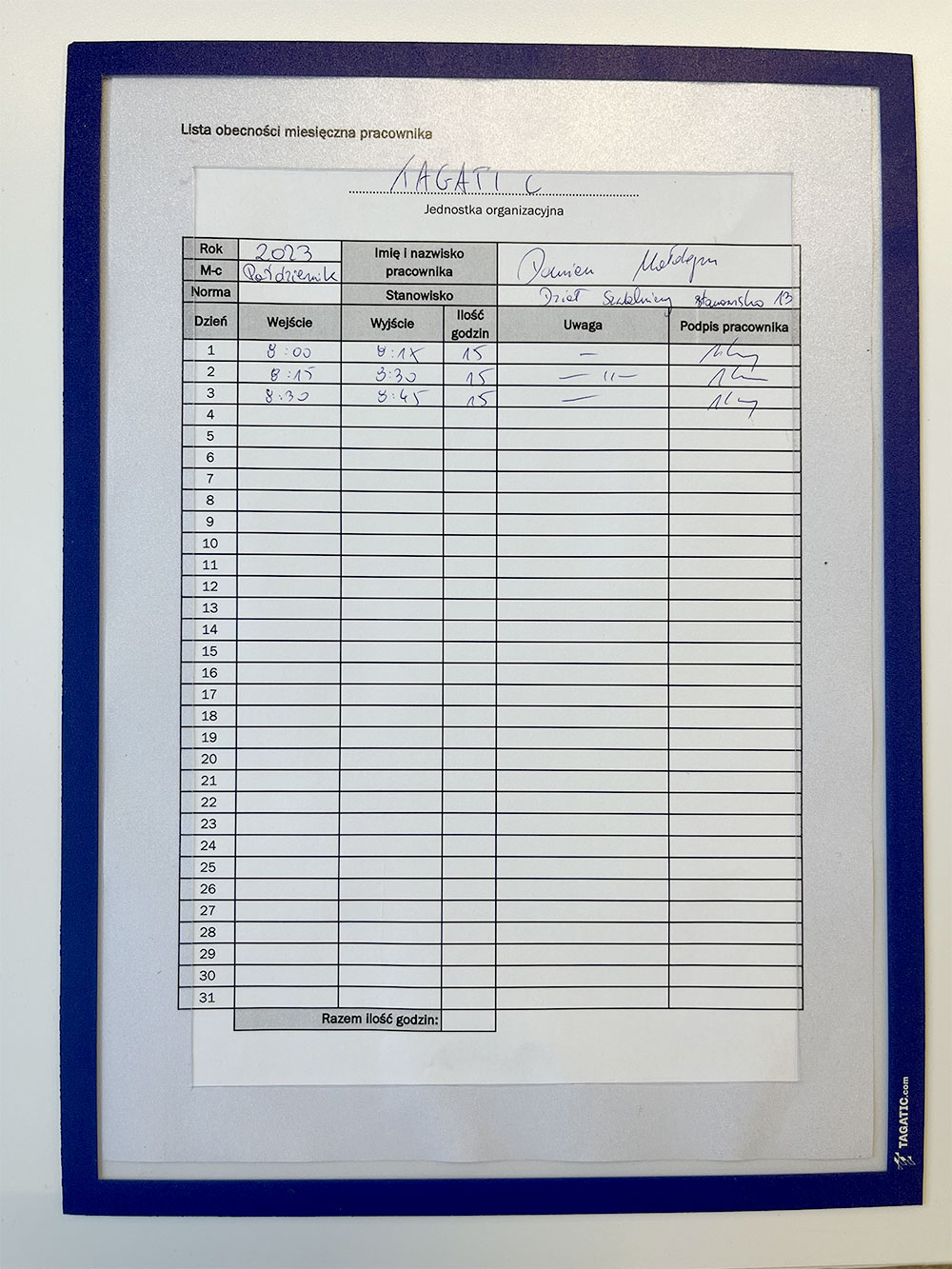

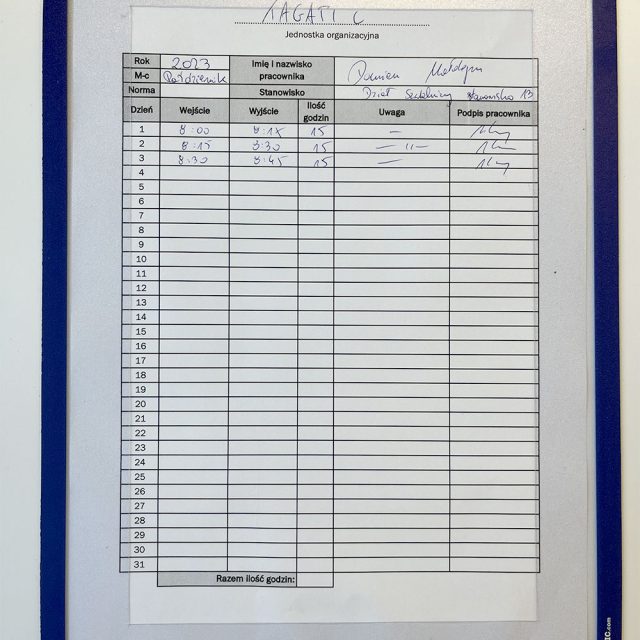

Our client operated a sewing department where the production cycle time was just 15 minutes. Employees were required to sign cards if the product was free from defects. This card was stored in a binder at the operator's feet level. The signing process required multiple steps, including bending down, searching for the card, pulling out a pen, and signing, which took a total of 27 seconds per production cycle.

Our Solution:

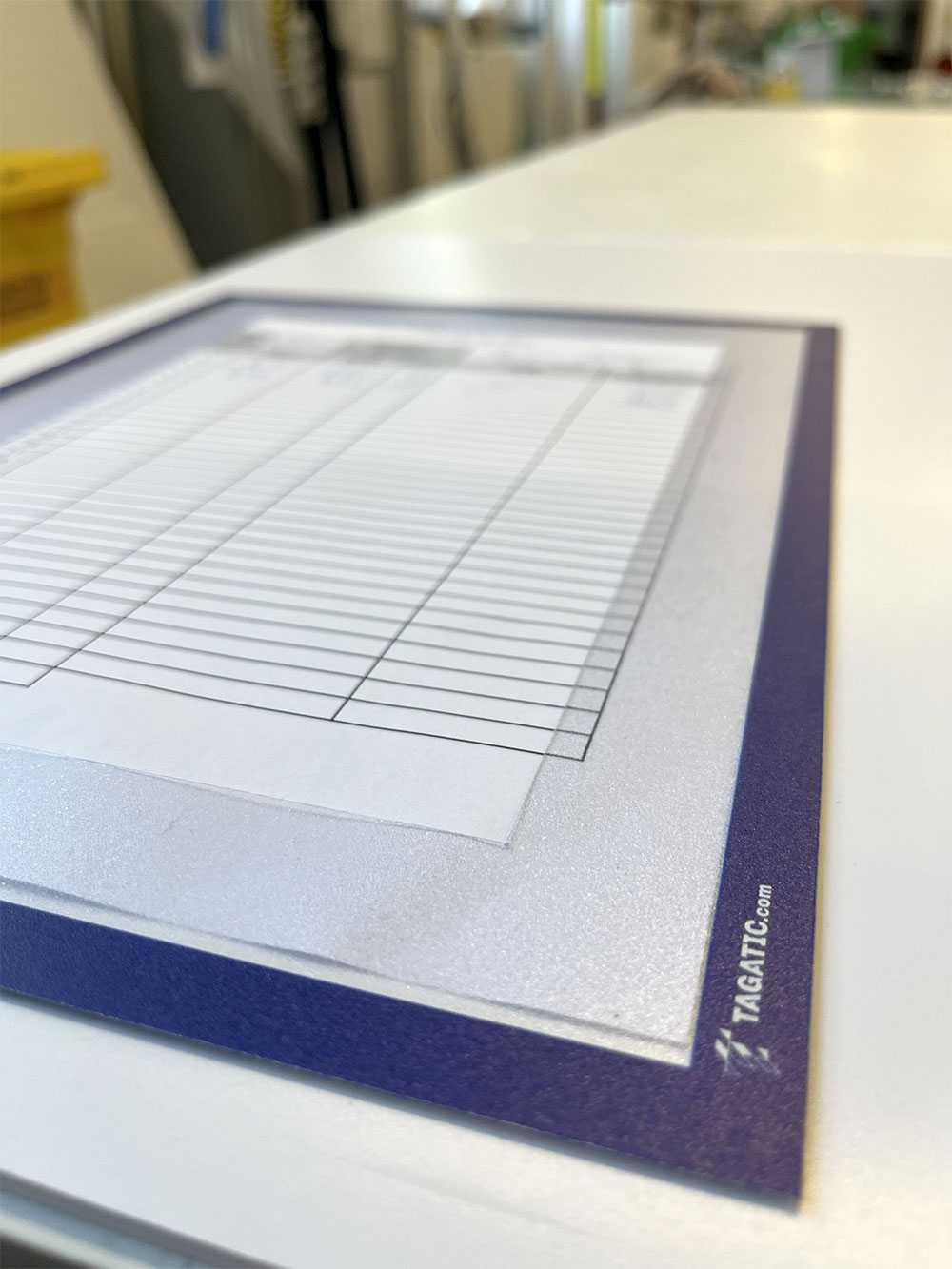

Our solution was to create a dedicated, thin, self-adhesive document frame with a cutout window for signing. This frame was mounted on the assembly table, significantly shortening the signing process. Now, employees simply had to draw a pen and sign the card, taking just 11 seconds per production cycle.

Result

Our optimization had a dramatic impact on work efficiency. Before the intervention, this time was 27 seconds, but after the optimization, it was reduced to 11 seconds. For one employee, this meant a saving of 9 minutes per shift.

Scale and Effects

The plant had 30 sewing stations, operated in two shifts. Thanks to optimization, 540 minutes of daily time were saved, allowing employees to produce 36 more products per working day – without changing their work pace. This demonstrates that even small changes can have a huge impact on efficiency in a large enterprise.

Summary

Our collaboration with a client in the manufacturing industry demonstrated how small changes to work processes can yield significant results. By optimizing the signature process, we significantly improved production, increasing efficiency. Our solution demonstrated to employees that improvement doesn't mean working faster, but rather better organization around production stations.

The most important conclusions from the cooperation:

- Small changes can produce big effects on a large scale.

- Improvements in work processes can lead to increased productivity without necessarily increasing the pace of work.

- Optimization can help free up valuable time for production workers, allowing for more products to be produced.