Olimp Labs Adaptation of assembly space

Cooperation

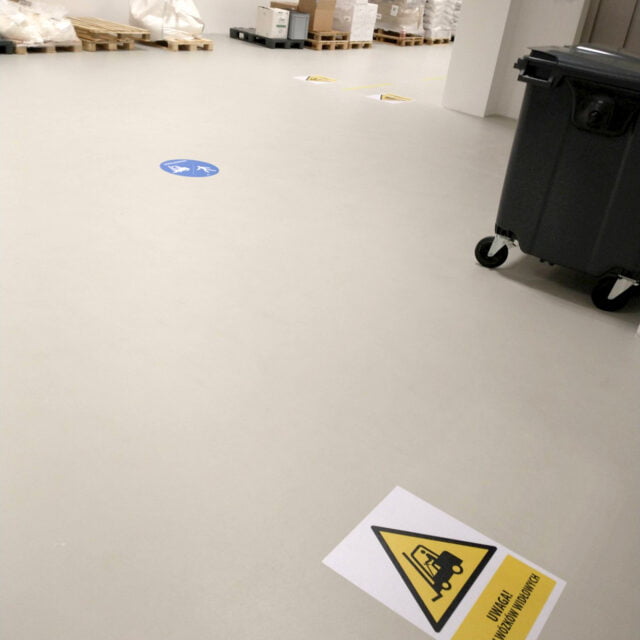

Our initial collaboration with Olimp Labs involved signage for the company's warehouse. As part of the project, we provided signage for packing stations, a cleaning corner, and storage area signage.

However, we soon faced a much greater challenge – creating a Visual Management System for a newly established production facility. This assignment presented us with a significant challenge, but also a unique opportunity to develop Visual Management during the factory's design phase.

Our tasks included developing all communication within the plant, as well as floor markings and equipping individual zones, including 5S shadow boards.

After the client approved the design and completed the work related to the construction of the production hall, we began to plaster the surfaces agreed upon in the design.

Adapting the project to the client's needs

Working in the newly constructed plant required us to analyze not the actual state of affairs, but rather designs and architectural schemes, within which we could propose and design the most effective communication routes – both for pedestrians and vehicles.

The key to the project was the speed and timeliness of assembly – so that on the opening day the factory met all health and safety requirements.

Consultations and advice

The nature of the project allowed us to fully utilize our existing knowledge and skills. We implemented the project from scratch, mapping out paths and developing solutions that would impact the overall operation of the plant. This required numerous consultations with the client regarding the proposed solutions and their feasibility. Planning assembly to complete the project within the short window between the factory's completion and the official opening was also crucial.

Post-implementation support

Due to the number of materials used, it's essential to monitor their condition and replace wear-and-tear components on an ongoing basis. Our products are highly durable, but the components used to mark production areas require inspections and replacements – after all, they serve to ensure safety and improve work efficiency.

All materials provided by Tagatic as part of post-implementation service are consistent with the layout and style defined and accepted by the Client.