Frito-Lay Polska Flexible production hall signage

Flexible and easy to modify system

Dynamically changing production processes in one section of the hall posed a significant challenge to typical signage solutions. The processes there are so repetitive that permanent markings (e.g., paint) would have been impractical and unstable. The client required a flexible, easily modifiable system that would allow the space to adapt to changing needs without interrupting operations.

Our solution

Rotation zone

For areas with variable process layouts, we proposed a system of adhesive tapes and floor markings that can be quickly replaced or modified. We selected the materials to be resistant to industrial loads, yet easy to apply and remove.

This solution still works well in everyday work – the Frito-Lay team completes the labels themselves, regularly using the products we recommend.

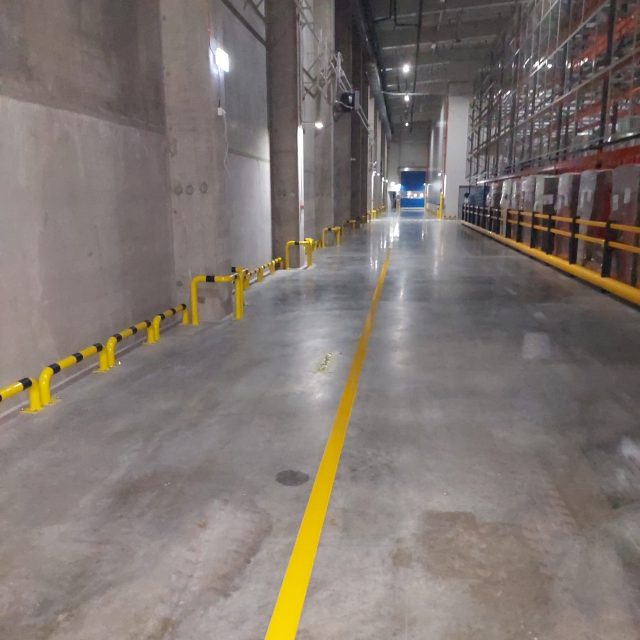

Communication routes

In zones with a fixed layout – primarily pedestrian and logistics routes, i.e. routes for transport trolleys and pedestrian traffic – we performed professional painting of horizontal markings .

The project included:

- planning routes based on production needs and logistics flow,

- selection of appropriate paints and technologies for the surface,

- full implementation with technical supervision.

Effects of cooperation

✔ The hall space has gained clear, functional markings that improve safety and traffic flow.

✔ Thanks to flexible solutions, the client can independently manage the signage in variable zones without the need for re-implementation.

✔ The cooperation that started with one project has been going on for over 2 years , and Frito-Lay Polska still regularly orders marking tapes and accessories from us in accordance with our previous recommendations.

Summary

This is another example of how effective industrial signage isn't just about painting lines. It's about tailoring solutions to real-world processes , understanding user needs, and designing a system that's flexible, durable, and compliant with health and safety standards.

For such a large and modern production hall as the Frito-Lay plant in Święte, functionality and adaptability – and that is exactly what we delivered.