DRADURA Polska Sp. z o. o. Design and installation of custom dry-erase boards

Technical challenges and solutions

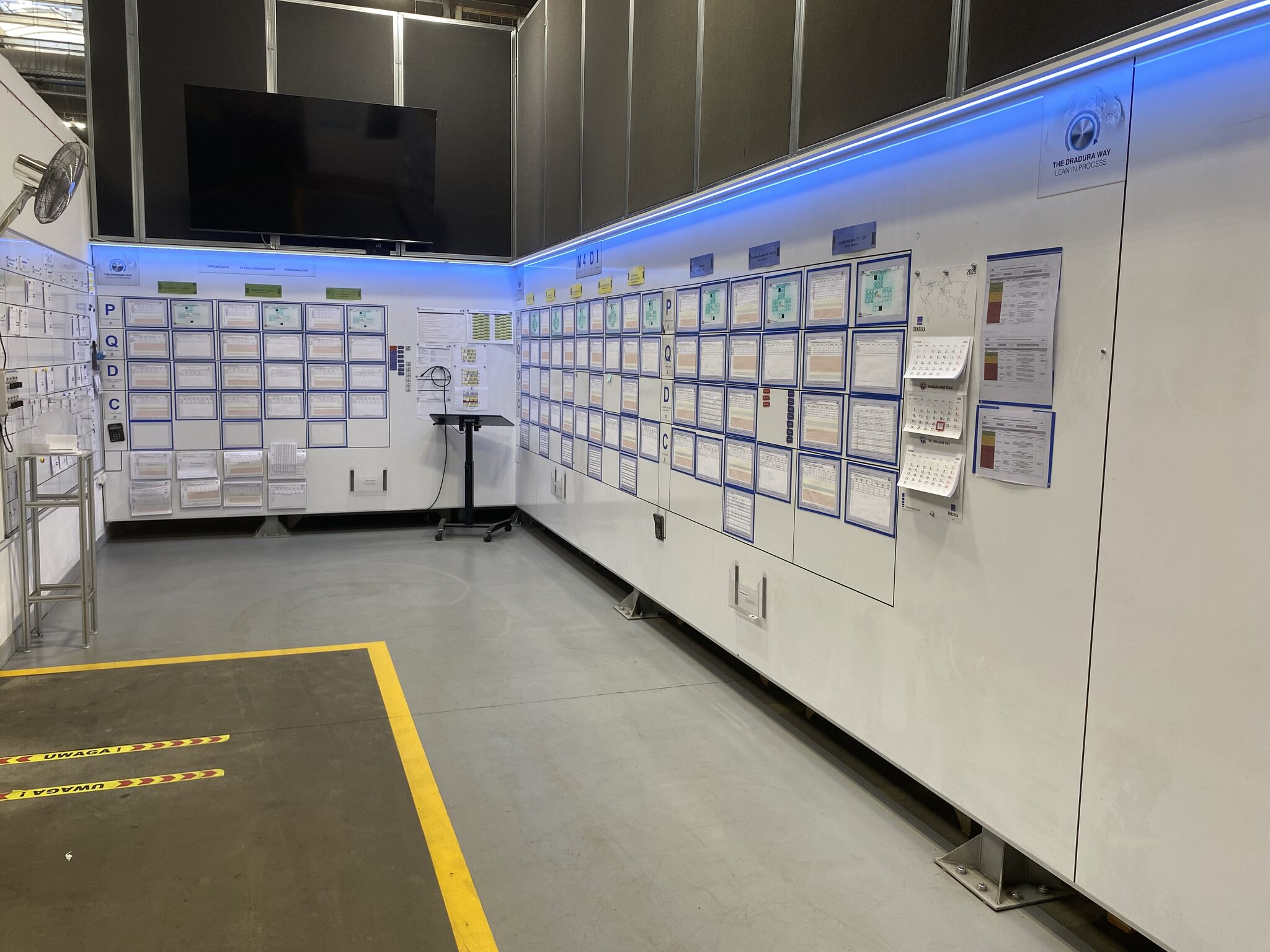

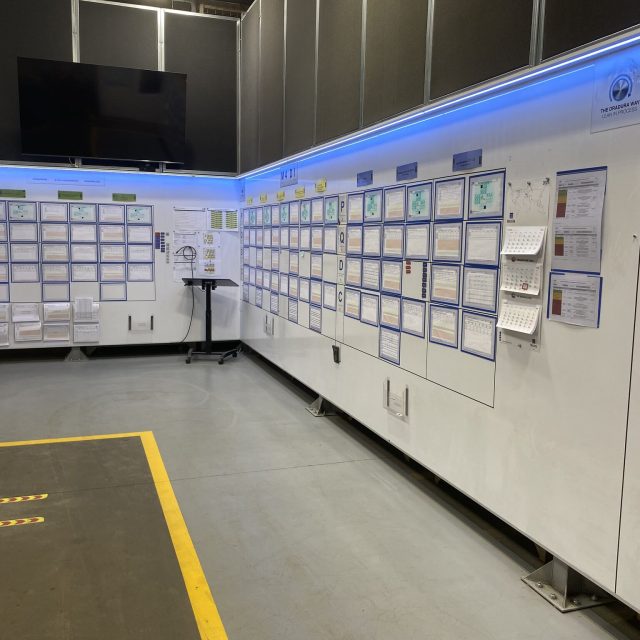

Installation on an existing structure

– adaptation to the hall conditions required precise measurements and a dedicated mounting system ensuring stability and safety of use.

LED backlighting with color control

– thanks to the use of a controlled lighting system, it is possible to dynamically adjust the light color to current operational needs. This is especially important in spaces where visual signaling supports the management of production and logistics processes.

Protection with powder-coated aluminum profiles

– increases the resistance of the boards to mechanical damage, which is crucial in a heavily used industrial environment.

Space optimization

– installing boards on existing walls and structures allows for maximum use of available space, eliminating the need to add new, space-consuming equipment.

Practical benefits

The project for DRADURA Polska is an example of how properly designed dry-erase boards can have a real impact on the daily operations of a production facility. Combining a personalized approach with modern technologies not only optimized the workspace but also streamlined internal communication and improved work ergonomics. The result is a solution that supports visual management, increases equipment durability, and complements the aesthetics of modern production facilities.

Improving the readability and organization of processes

Boards support visual production management, which translates into more effective internal communication.

Increased durability and ergonomics

Dedicated materials and technologies used in the implementation guarantee many years of operation without loss of quality.

Modern design

Aesthetics that go hand in hand with functionality improve the user experience and the image of the facility.