Industrial Marking Audit

What does an audit include?

On-site inspection

Photographic documentation

Key zone analysis

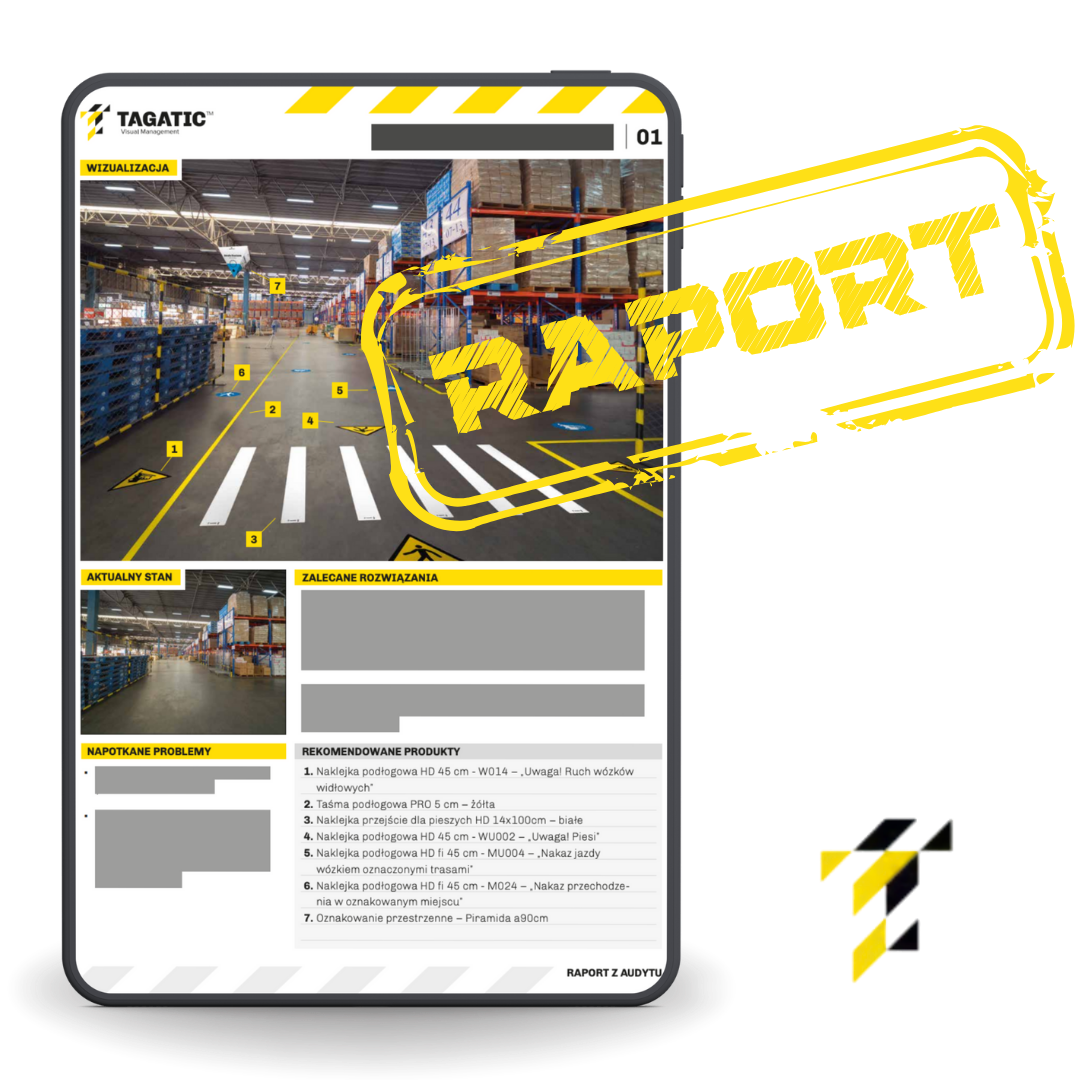

Audit report

At this stage, you decide which elements from the report you would like to implement. You will also receive a quote for the entire change we propose (covering all stages of the process: from solution design, through production, and delivery). You can outsource the installation to us or handle it yourself.

Take the first step

and schedule an audit

With us, you can streamline processes, improve safety

, and optimally utilize the space in your facility.

Fill out the form

REGULAR AUDIT PRICE: PLN 1999 net

If you decide to implement

the first project recommended in the report

YOU WILL PAY 0 PLN

(the promotion is valid for a maximum of 30 days from the date of sending the offer after the audit)

Why is it worth it?

Compliance with current occupational health and safety regulations and EU standards

A clear action plan and specific recommendations

Reducing accidents and downtime costs

Minimizing financial risk

Better organization and smooth processes

Professional image and audit under control

CHOOSE TAGATIC

Thanks to our own production and design team, we are able to go straight from audit to implementation with full quality control

Durable, high-quality products

Cooperation with specialists

Support and education

Want to discuss details?

Reference

LG Innotek Poland Sp. z o. o.

TAGATIC Sp . z o. o. provides our company with top - quality solutions . We can always count on professional assistance and advice .

Nefab Packaging Poland Sp. z o. o.

The professionalism of the service and the substantive knowledge of the entire Tagatic team have, in many cases, contributed to the implementation of a large number of our projects and allowed us quickly and efficiently implement creative solutions within our organization . TAGATIC products are delivered on time and to the highest quality .

Sev-Eurodrive Polska Sp. z o. o.

We are pleased to announce that Tagatic is our long-term partner in providing visual management services and printing product delivery throughout Poland . a , , a partner in implementing VM solutions.